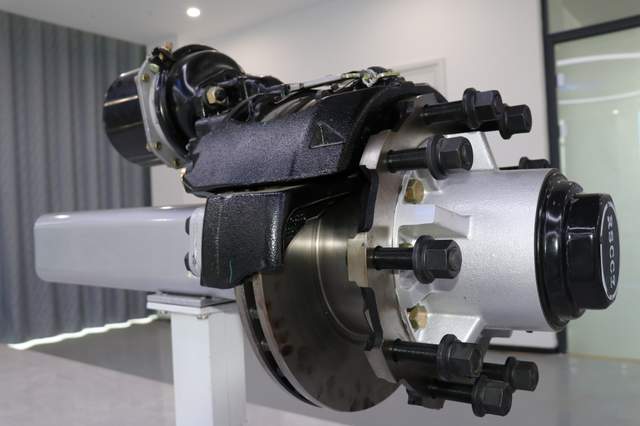

The axle is one of the core components of the trailer. Its quality and performance are directly related to the driving safety of the trailer, such as load-bearing, braking, driving maintenance and so on. A high-quality axle has high processing accuracy, good load-bearing performance, sensitive and efficient braking, long maintenance cycle, and good cooperation between various parts, which can protect and reduce tire wear, not only ensure vehicle safety, but also help car owners reduce the cost of comprehensive vehicles.

But like other consumer goods on the market, there are fake and shoddy products on the axle. These fake axles have poor braking effect and poor operation performance. The axle beam, bearing and wheel hub are easy to be damaged. At least, they lead to tire eccentric wear. Although they do not affect the driving, they increase the cost of many vehicles. At worst, they are easy to lead to safety accidents, such as brake failure, axle fracture, bearing damage, tire detachment, etc. any kind of accident occurs in the process of high-speed driving, and the consequences are unimaginable, Transportation safety is not guaranteed.

The reason why the quality of these fake and shoddy axles is not up to standard is largely related to their production technology. For example, if the strength of the selected raw materials is not enough or the parameters are falsely marked, the process in the production process is backward and can not meet the industrial standards, and the straightening and heat treatment of the axle are unqualified, it is easy to cause the deformation of the axle after leaving the factory, which will directly lead to the failure of the trailer in use.

If you want to produce a qualified axle, you must strictly control it from the beginning of raw materials. Raw materials are the basis of all performance. Only by ensuring that the thickness, strength and toughness of raw materials meet the design indicators, can the subsequent series of processing procedures be meaningful.

After the raw materials are selected, first cut them with a sawing machine according to the size of the drawing for subsequent processing;

After blanking, it enters the hot rotary rolling process. Through the heat treatment technology up to 1300 ℃, it reduces the molding resistance and deformation energy consumption of raw materials, and reduces or eliminates casting defects;

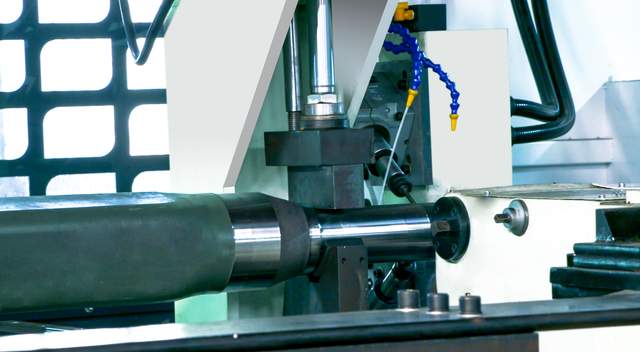

After cooling, the shaft head shall be cut to ensure that the size of the shaft head meets the requirements;

If it is a square shaft tube, then it needs to be cold pushed to ensure one-time forming, so as to reduce and avoid material bending. If it is a circular shaft tube, it does not need to be pushed to directly enter the quenching process;

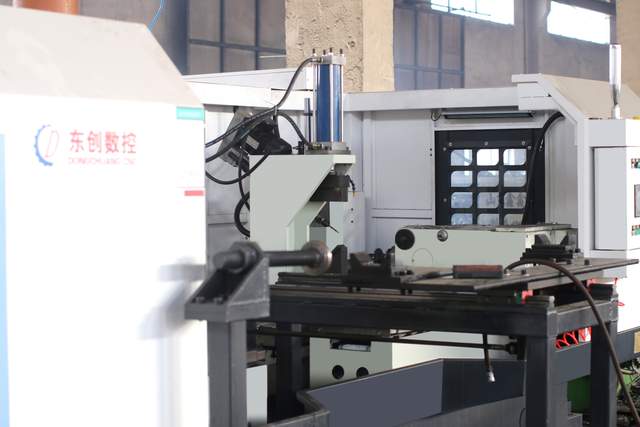

Digital medium frequency induction equipment is adopted to ensure the operation accuracy. Under high temperature treatment, the stiffness, wear resistance and fatigue resistance of the material are improved again;

Tempering must be carried out after quenching to eliminate the internal stress of raw materials in the quenching link and improve the ductility and toughness of shaft body;

The next step is shot blasting to remove the residual oxide scale and oil stain in the heat treatment process to improve the finish;

Then the multi-point straightening machine is used to straighten the shaft tube on line;

Followed by CNC processing, including boring, washing and milling, drilling, CNC machine tools, etc., to ensure the high precision of products;

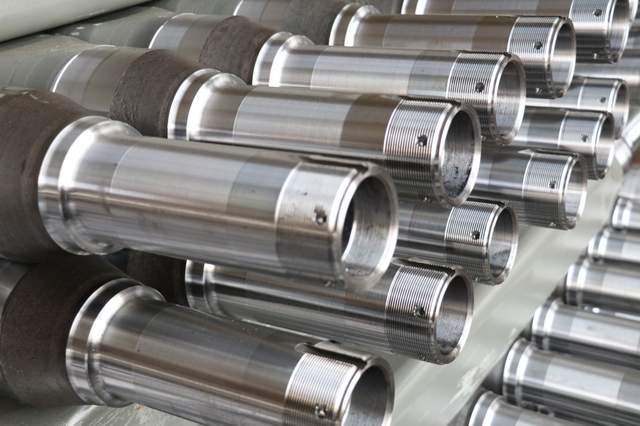

Next, carry out medium frequency induction treatment for the key parts of the connecting bearing, combined with further finishing, so as to improve the safety and stability of the axle to a greater extent. After completion, enter the comprehensive inspection link and pass the inspection, that is, the optical axis semi-finished products.

After that, welding, painting and installation of shaft head nut locking gasket are carried out. After this step, semi-finished welding products are obtained.

Finally, the welded semi-finished products are assembled with special bearings and hubs to make an axle. After the quality inspection and performance test of the finished products are qualified, a high-quality axle is completed.

It can be seen that the production of axle is not a simple thing. If there is a problem in any link in the production process, the final finished product quality will not meet the standard. Therefore, to buy a car bridge, you still have to choose a reliable brand.

However, a large part of the reason why some car owners buy fake and shoddy products is because of the cost. Now the axles of major brands on the market are expensive. For example, the unit price of the new disc axle can be more than 90 million yuan. If a car needs three axles, the cost is about 30000 yuan.

However, car owners should not be confused by the initial price. Although inferior axles are sold cheaply, the cost of subsequent use is expensive. Instead of reducing the cost, it is much higher. Moreover, not all qualified axles in the market are sold at extremely high prices, but there are still some brands with reliable quality and affordable prices. For example, Darong axle, as the first batch of enterprises producing integrated axles in Liangshan commercial vehicle base, has gone through 20 years, and its strength and technology are trustworthy. The above series of production steps are a true portrayal of Darong factory, Many Trailer enterprises and logistics companies choose Darong as a fixed axle partner, with high cost performance, affordable products, saving money and worry, which has won wide praise from market users.

ONLINE MESSAGE

24-hour consultation telephone

24-hour consultation telephone

400-6363-989

If you have any needs, you can contact us

CONTACT US

Customer Service Hotline:400-6363-989 Company Address:No. 2, Guoyuan Road, Industrial Park, Quanpu Town, Liangshan County, Jining Cityall rights reserved Darong traffic machinery Co., LTD Lu ICP No. 20025388-2