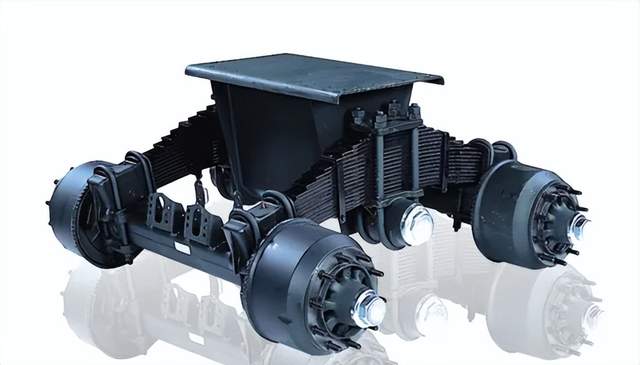

Trailer axle is a typical support axle, which is composed of axle beam, camshaft, brake assembly, wheel end assembly, adjusting arm, various washers, bolts, etc., and is mainly used to bear the body weight. In addition to load, it can also play a role in assisting vehicle braking, maintaining vehicle driving, mitigating bumps, etc., without steering and driving functions.

From the view of vehicle structure, the axle belongs to a part of the vehicle chassis and belongs to the driving system. How is the axle connected to the chassis?

Before answering this question, let's take a look at the four major systems of the vehicle chassis:

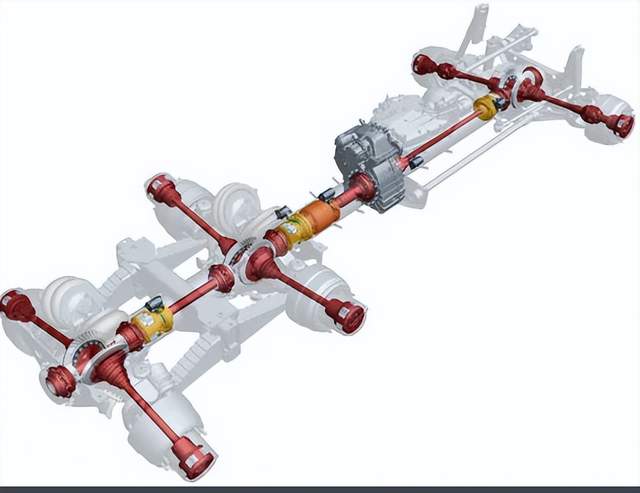

1. Transmission system: mainly including clutch, transmission, universal transmission, final drive, differential and half shaft.

2. Driving system: In addition to the axle just mentioned, it also includes the frame, suspension, wheels, etc.

3. Steering system: including steering wheel, steering shaft, steering column, etc.

4. Braking system: mainly composed of energy supply device, control device, transmission device and brake.

These four systems together form the vehicle chassis, which is used to support and install the vehicle engine and other various components and assemblies, form the overall shape of the vehicle, assume the engine power, and ensure the normal driving of the vehicle.

We can see that the chassis driving system where the axle is located also includes the frame, suspension and wheels. Both ends of the axle are used to connect the wheels, and the upper part is connected to the frame through the suspension.

In other words, the trailer axle is generally connected to the suspension, and then the suspension is connected to the frame and fixed on the chassis.

Now that I have said this, I would like to share with you some knowledge about the lower frame and suspension.

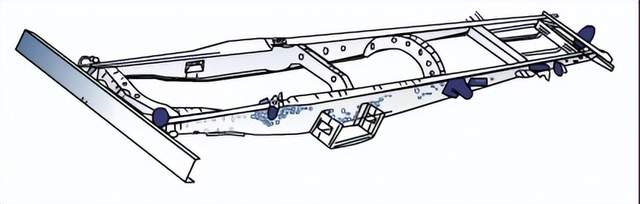

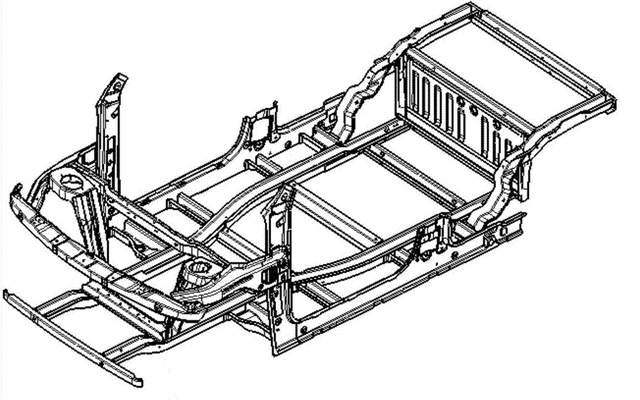

Frame: refers to the bridge type structure that spans between various vehicle bridges, is also the installation foundation of vehicles, and is a rigid structure composed of longitudinal beams and cross beams, which can be divided into edge beam type, center beam type, integrated type and beamless type.

1. Side beam frame: also known as trapezoidal frame, it is a solid rigid frame formed by two longitudinal beams on both sides and several cross beams through riveting or welding, which is widely used in commercial vehicles.

2. Center frame: There is only one longitudinal beam in the center that runs through the entire length of the car, also known as the spine frame. The structure of the frame can allow the wheels to have a large jumping space, which is convenient for the installation of independent suspension, and is light in weight, low in gravity center, and high in strength and stiffness; The disadvantages are that the process is complex, the accuracy requirement is high, the assembly is difficult to install, and the maintenance is inconvenient. Therefore, the application is less at present, and it is generally used on off-road vehicles.

3. Integrated frame: also known as composite frame, it refers to the frame with front part of side beam and rear part of center beam. It has the characteristics of center beam and side beam frame. The side beam is used to install the engine, and the overhanging bracket is used to fix the body. In essence, it is a deformation of the center beam frame. Of course, the structure is more complex, and it is mainly used for racing cars or special vehicles.

4. Beamless frame: it is a load-bearing body. As the name implies, it does not have a separate frame. Instead of the frame, the body is used. The main components are directly connected to the body. The advantages are good stiffness, light weight, and good coordination with each component. The disadvantages are that the production process is complex. At present, passenger cars and some buses basically use this frame form.

Suspension: refers to the component connecting the frame and the axle, which is used to transmit the force and torsion between the wheel and the frame, buffer the impact force transmitted to the frame or body from uneven road surface, reduce the vibration caused thereby, and ensure the smooth running of the vehicle. It can be mainly divided into four categories: rigid suspension, single point suspension, steel plate suspension, and air suspension.

1. Rigid suspension: the left and right are connected by one axle, and the chassis directly acts on the axle. The shock absorption effect of this type is very poor, and it is seldom used at present. It is mainly used on the axis for low-speed cargo transportation.

2. Single point suspension: reduce the common front and rear steel plate spring supports to a single support and connect it to the vehicle body. Its stress points are shared on the front and rear axles. Compared with ordinary steel plate spring suspension, it has greater bearing capacity. It is less used on ordinary semi trailers and is mainly used on heavy vehicles.

3. Steel plate suspension: it is our common steel plate spring. Its full name is tandem steel plate spring balanced suspension. It is mainly composed of leaf spring, suspension support (commonly known as lifting lug), connecting rod, U-bolt, etc. The biggest advantages of this suspension are its low price, good reliability and convenient maintenance. At present, more than 80% of domestic ordinary semi trailers use leaf spring balanced suspension.

4. Air suspension: The most obvious feature of air suspension is its airbag type air spring, which is light in weight, low in friction, almost noiseless in operation, and has a service life of 2-3 times that of leaf spring. However, it is complex in structure, strict in sealing requirements, and high in cost. At present, domestic air suspension is mostly used in high-end fields such as precision instrument transportation, tobacco transportation and hazardous chemical transportation. It is worth mentioning that hydro pneumatic suspension is strictly a kind of air suspension, which is mainly used for large mining vehicles, multi axle special off-road vehicles, armored vehicles and other models.

How to install the trailer axle?

If you have any questions about the subsequent installation and use after purchasing the Darong Axle, please call 400-6363-989 or leave a message directly.

ONLINE MESSAGE

24-hour consultation telephone

24-hour consultation telephone

400-6363-989

If you have any needs, you can contact us

CONTACT US

Customer Service Hotline:400-6363-989 Company Address:No. 2, Guoyuan Road, Industrial Park, Quanpu Town, Liangshan County, Jining Cityall rights reserved Darong traffic machinery Co., LTD Lu ICP No. 20025388-2