The axle is an important part of the vehicle chassis, which is related to the vehicle's walking, braking, steering, load-bearing and so on. According to different functions, common axles can be divided into four types: steering axle, drive axle, steering drive axle and support axle.

1. Steering axle.

It refers to the axle that undertakes the steering task in the vehicle. In addition to the vertical load of the vehicle, it also bears the longitudinal force, lateral force and the torque caused by it.

The working principle of the steering axle is mainly to use the steering knuckle in the axle to deflect the wheels at both ends at a certain angle to realize the steering of the vehicle. Generally, it is used in the front of the vehicle. Therefore, it is often called the front axle. The structure is mainly composed of front beam and steering knuckle.

The steering axle can be divided into integral type and disconnected type:

The integral steering axle usually adopts I-beam with I-section or tubular beam with tubular section. The middle part is bent downward, and the kingpin and steering knuckle are installed at both ends. It adopts leaf spring suspension. This structure is generally used for cargo vehicles.

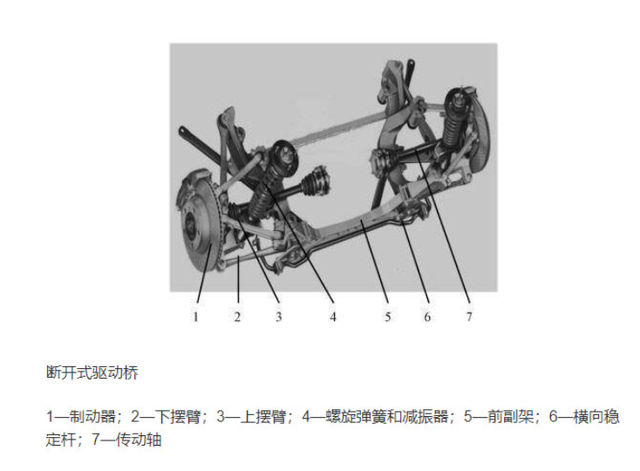

The wheels at both ends of the disconnected steering axle are connected with the vehicle body through independent suspension. Most steering axles of micro cars adopt this structure.

2. Drive axle.

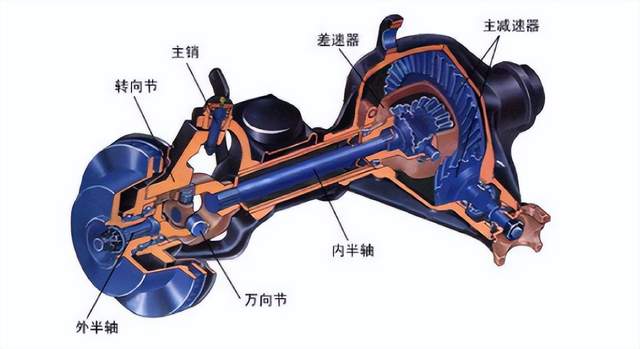

The drive axle is an axle installed at the end of the transmission system, which can change the speed and torque from the transmission and transmit them to the drive wheels. In short, the function of the drive axle is to distribute the torque of the engine to the left and right drive wheels after reducing the speed and increasing the torque and changing the power transmission direction to drive the vehicle. Generally, it is mainly composed of reducer, differential, axle shaft and axle housing.

The drive axle can also be divided into two types: non disconnecting drive axle and disconnecting drive axle, which are also distinguished by whether to use independent suspension. Generally, non disconnecting drive axle is widely used in freight vehicles.

In addition, from the perspective of structural form, the drive axle can also be divided into three categories: Central single-stage deceleration drive axle, central double-stage deceleration drive axle and central single-stage wheel side deceleration drive axle:

The central single-stage deceleration drive axle is the simplest type of drive axle structure, which is dominant in heavy-duty trucks;

The central two-stage deceleration drive axle is a model derived when the speed ratio of the single-stage axle exceeds a certain value or the total traction mass is large;

Wheel side deceleration drive axle is widely used in off-road vehicles and military vehicles such as oil fields, construction sites and mines.

3. Steering drive axle.

For front wheel drive vehicles and all wheel drive vehicles, the front axle should not only bear the steering function, but also transmit power, so it is called steering drive axle. In terms of structure, it should not only have the main reducer, differential and axle shaft of general drive axle, but also the steering knuckle and kingpin of steering axle.

4. Support bridge.

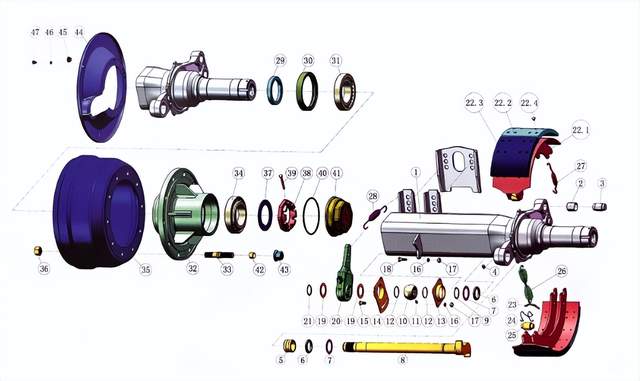

Support axle, as the name suggests, refers to the axle that has neither steering function nor driving function and is specially used to bear the weight of the vehicle body. It is generally used on the semi-trailer chassis behind the tractor. It is mainly composed of axle beam, metal support seat, wheel assembly and other components. In addition to the weight of the load body, it can also alleviate road bumps, ensure vehicle braking, maintain vehicle driving, etc.

Although in terms of function, the support bridge is relatively simple among the four axle classifications, its structure and composition are not simple. There are nearly 100 optical parts of a support bridge, which belongs to a real precision machinery.

According to different use requirements and structural forms, support bridges can be subdivided into many types. Taking Darong axle as an example, it can be divided into disc type, drum type, low flat plate, single / double tire, internal / external, concave type, three wire six axle, special axle, etc.

Among them, the disc axle is mainly applicable to the "delicate" transportation of dangerous chemicals, precision instruments, vegetables, fruits and flowers and other goods with strict requirements on cargo damage rate; Drum axle is mainly used for heavy cargo transportation or ordinary cargo transportation, with low cost and simple maintenance; Low plate axle and three line six axle axle axle are mainly used in large plate vehicles or large transport vehicles, with low center of gravity, strong stability and trafficability, convenient loading and unloading of goods and stronger load-bearing capacity.

As for which axle is the best, we also need to comprehensively consider the transportation needs and working conditions of vehicles. After all, what is suitable is the best, and we must not blindly follow suit.

ONLINE MESSAGE

24-hour consultation telephone

24-hour consultation telephone

400-6363-989

If you have any needs, you can contact us

CONTACT US

Customer Service Hotline:400-6363-989 Company Address:No. 2, Guoyuan Road, Industrial Park, Quanpu Town, Liangshan County, Jining Cityall rights reserved Darong traffic machinery Co., LTD Lu ICP No. 20025388-2