The axle is an important component of the vehicle, which directly affects the performance and cost of the vehicle. Especially for transportation vehicles, the appropriate and durable axle can greatly improve the transportation efficiency and increase the operating income of vehicle owners. In general, the axle can be divided into four types: steering axle, drive axle, steering drive axle and support axle. What kind of wheel axle and axle shaft axle belong to?

In terms of classification, wheel side axle and axle shaft axle belong to drive axle, but there are many differences in structure and performance.

Half axle axle, also known as single-stage reduction axle, is also called big belly axle by many car owners, because its differential case is relatively large and its shape is very similar to the big belly of axle, so it is named. Its structure is relatively simple. The main reducer is composed of a driving bevel gear (commonly known as angle gear) and a driven bevel gear (commonly known as basin gear).

Because of its simple structure, it has light self weight, low failure rate and simple maintenance. However, when the road conditions are poor, the half axle bridge appears to be a little weak. One is the insufficient torque amplification, and the other is the excessive differential housing, which affects the trafficability of the vehicle.

Wheel side axle, also known as wheel reduction axle, its scientific name is two-stage reduction axle. Its structure is relatively more complex. It has a group of reduction transmission at the wheel side than the half axle axle axle. Because it realizes the reduction speed ratio through two-stage transmission, the differential housing in the middle is much smaller than the half axle axle axle and has better trafficability. Under the same reduction speed ratio, it can bear greater input torque.

For the wheel side axle, the differential case is relatively small, the ground clearance is larger, and the trafficability is stronger. In addition, the biggest function of wheel reducer is to reduce speed and increase torque, so it has large torque and stronger driving force. Of course, there are advantages and disadvantages. Firstly, its structure is more complex and its transmission efficiency is relatively poor. Secondly, when driving at high speed, because the wheel reducer undertakes most of the tasks of speed change and torque increase, the heat generated by the friction between the tire and the ground is concentrated at the wheel end, resulting in poor heat dissipation conditions. In addition, the assembly and maintenance technology requirements of wheel side bridge are high, which is not as simple as half axle bridge.

As for the selection of wheel side bridge and axle shaft bridge, it should be judged according to the actual use needs of the vehicle. If the vehicle runs at a high speed and the road condition is good, and the standard load is mainly used in the distribution of goods, it is relatively more suitable for the half axle bridge and is better in lightweight. It not only has lower fuel consumption, but also does not have to worry about the high temperature phenomenon of the axle head due to long-term high-speed driving; If there are many vehicles running off the road, or the driving road conditions are complex, and the distributor mainly focuses on heavy load, it is more suitable for wheel side bridge, with small volume, high trafficability and stronger difficulty relief performance.

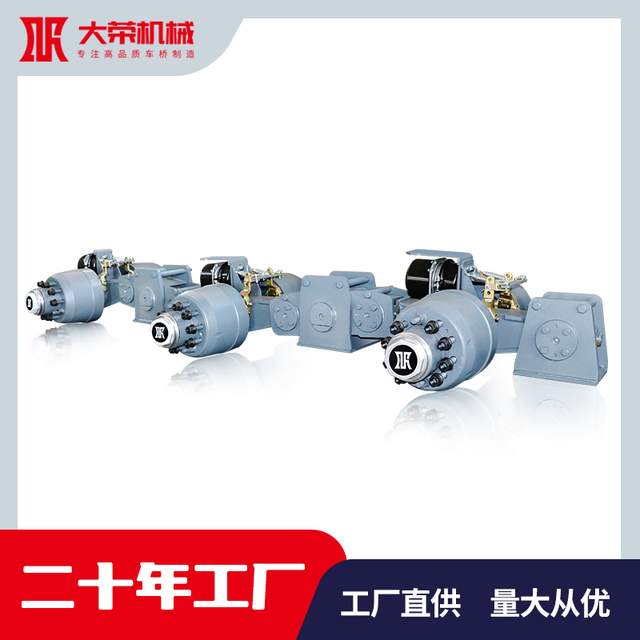

In fact, for the semi-trailer commonly used in the logistics and transportation industry, the drive axle is mostly installed on the tractor, and the trailer bucket loaded with goods is generally installed with the support axle, which does not bear the steering or driving. Its main function is to bear the load, cushion the bumps on the road, ensure the vehicle braking and maintain the vehicle driving. In terms of types, it can be subdivided into disc axle, drum axle, low flat axle, three-line six axle axle axle axle axle, etc, It is suitable for different fields according to its design and performance.

1. Disc axle.

The biggest feature of disc axle is lighter weight, exposed brake disc, faster heat dissipation, more sensitive and stable braking, less overheating under continuous braking, and more stable heat attenuation performance.

In addition to the current mandatory installation of three axle warehouse fence plate trailers, disc axles are mainly used in cold chain transportation, dangerous chemicals transportation, precision equipment or precious goods transportation. Due to its relatively small braking force, it is recommended to use with hydraulic retarder for general heavy-duty trucks.

It is worth mentioning that the disc axle is more suitable for use with hydraulic retarder and ABS / EBS system, which can give full play to their respective efficiency and make the vehicle achieve the best braking effect.

2. Drum axle.

Drum axle is characterized by large braking friction area, large braking force, stronger economy and convenient maintenance. However, due to the poor heat dissipation of the sealed brake drum, in order to avoid heat attenuation, it is necessary to be equipped with a water spraying device to cool down during continuous braking. Drum axles are generally more suitable for heavy transport vehicles.

3. Low flat axle.

Low flat car bridge is specially built for low flat trailer. It is suitable for the transportation of a variety of mechanical equipment, large objects, highway construction equipment, large tanks, power station equipment, steel, vehicles and other goods. Its center of gravity is lower and its height is designed to be shorter than other car bridges, which is convenient for goods to get on and off, as well as vehicles to pass through height limited sections, with higher transportation stability. The axle of low flat axle adopts special thickened steel, which has higher strength and better bearing performance.

4. Three wire six axle axle.

The three line six axle axle axle is mainly applicable to the transportation of large pieces / extra large pieces. This kind of goods has a large volume and weight and is generally non detachable, requiring large or special vehicles for transportation. The three wire six axle axle axle is specially customized for large transport vehicles, with a load of up to 80t and a large number of tires, so as to reduce the average pressure on the contact surface and reduce the damage to tires and roads.

Darong group is one of the first batch of axle enterprises producing integrated axle body in China, and its axle casting technology and process are at the leading level in China. Darong group has built a 32000 ㎡ standardized plant. More than a dozen processes from blanking to assembly are carried out in accordance with industry standards and specifications. The ex factory axles have undergone Online + offline dual quality inspection and limit performance test. The quality is reliable and trustworthy. Since its establishment, Darong group has always adhered to the route of high price performance ratio, aiming to enable users to buy higher quality axles at more affordable prices

ONLINE MESSAGE

24-hour consultation telephone

24-hour consultation telephone

400-6363-989

If you have any needs, you can contact us

CONTACT US

Customer Service Hotline:400-6363-989 Company Address:No. 2, Guoyuan Road, Industrial Park, Quanpu Town, Liangshan County, Jining Cityall rights reserved Darong traffic machinery Co., LTD Lu ICP No. 20025388-2