With the increasingly strict supervision of the load capacity of semi-trailer by relevant departments, lightweight has gradually become the object of attention in the industry. Under the same load limit, the lighter the trailer itself, the more goods it can carry. Therefore, many car owners also prefer lightweight trailers or trailer accessories.

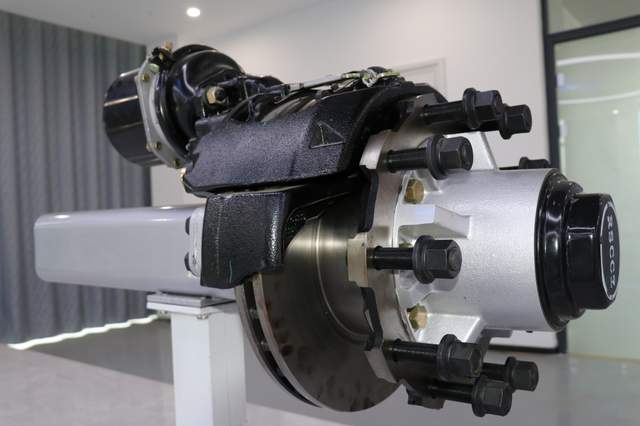

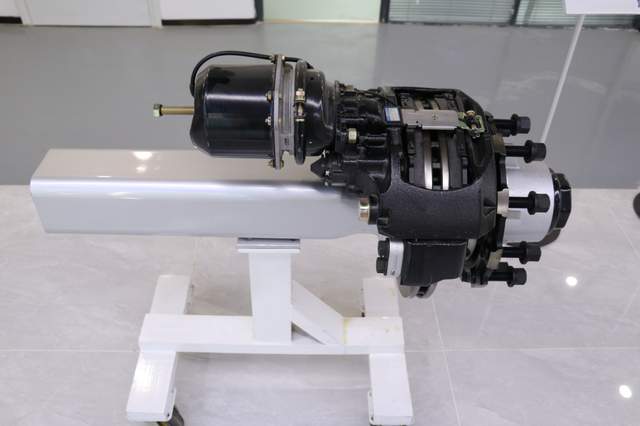

As we all know, the use of disc axle and airbag suspension is one of the ways to lighten the trailer. However, in the process of promoting the disc axle, it has been questioned by many car owners. Many car owners think it is not suitable for semi-trailer at all. The reasons are as follows: the temperature rises quickly, the water is easy to break, the braking force is small, and so on.

As a braking method highly praised by the state, is the disc axle really so unbearable? This is not the case. Next, let's make a detailed analysis of several issues that car owners are more concerned about.

1. Disc axle heating up too fast?

Why does the disc axle heat up faster than the drum? This starts with the structure of the disc axle.

Compared with the traditional drum axle, the volume of the disc axle is smaller, especially the friction area during braking, which is much smaller than the drum axle. Because the friction area is small, under the same braking load, the temperature of disc axle does rise faster than that of drum axle.

However, we should not forget that the brake disc and friction plate of the disc axle are directly exposed in the air, and its heat dissipation speed is much faster than that of the drum type. Therefore, although the temperature rises quickly, the temperature drops quickly, generally there will be no overheating.

Even if the temperature rises, the heat attenuation performance of disc axle is higher than that of drum axle. According to the comparison of experimental data, when the temperature of friction plate of drum brake reaches more than 300 ℃, the friction coefficient will decrease by 40% - 50%; When the temperature of disc brake friction plate rises from 100 ℃ to 400 ℃, the friction coefficient hardly changes.

What if some vehicles really need to run on mountain roads often? It can also be matched with auxiliary braking devices such as hydraulic retarder. The hydraulic retarder is not only light in weight, but also more reliable. With its help, the friction force of the brake disc can be greatly reduced, which can not only ensure the braking force, but also effectively avoid the overheating of the brake disc, and prolong the service life of the disc brake.

2. Small braking force of disc axle?

It is also because the braking friction area of disc axle is smaller than that of drum axle, and its braking force, especially for fully loaded heavy semi-trailer, is also smaller than that of drum axle to a certain extent, which is one of the reasons why disc axle is widely used in passenger cars and less used in semi-trailer.

However, this problem is not irreconcilable. As we mentioned above, for trailers that often transport heavy goods, or trailers that often need to run on mountain roads, it can be used with tractor braking devices such as hydraulic retarder, which can make up for the disadvantage of small braking force of disc axle.

In addition, car owners need to understand that although the braking force of disc axle is smaller than that of drum axle when used alone, it is better than drum axle in braking response speed. The brake system of drum axle has a set of complex structures, such as brake drum, wheel cylinder, adjusting arm, etc. when the owner steps on the brake, these components need to react one by one, and finally realize braking, which fills the response speed to a certain extent. The disc axle is different. There are not so many transfer devices in it. The wheel cylinder can directly push the caliper for braking, so the response speed is faster and the braking is more timely.

It can be seen that once the disc axle is equipped with hydraulic retarder, it will realize the super combination of fast braking response, strong braking force, more stable and reliable braking. On this basis, if the vehicle is equipped with ABS and EBS systems, the wheel locking can be prevented in the case of emergency braking, and the trailer can stop smoothly in the shortest distance, which is far better than the traditional drum axle.

3. The disc axle is easy to be damaged by water

In the past, many car owners liked to cool the axle by pouring water when using the drum axle. But after changing the disc axle, this practice is very undesirable. Why?

Because the brake system of drum axle is wrapped in the brake drum and has a closed structure, the speed of natural cooling is very slow during vehicle driving, so it needs to be cooled by spraying water. However, the disc axle is a non closed structure, and the cooling speed is very fast during the driving process of the vehicle, so there is no need to spray additional water for cooling.

In addition, in the case of disc axle without auxiliary device, if it needs long-time continuous braking such as long downhill, especially when the vehicle load is relatively large, the temperature rise of brake disc and friction plate is very obvious, and in some cases it can even reach 700 °. If it is poured directly with cold water when the brake disc is red, the temperature will drop by several Baidu instantly, It is easy to damage the brake disc. Therefore, the drenching cooling device is really not suitable for disc axle.

The car owner asked: isn't it easy for the disc axle to break down in rainy days?

No, the disc axle is easy to break when it is drenched with water to cool down, because a large amount of cold water is poured on the red brake disc in an instant. In contrast, the water drenching on the axle in rainy days is continuous, uniform and non centralized, so it will not cause damage to the brake disc, especially for vehicles equipped with hydraulic retarder.

In addition, the owner needs to understand that after the trailer wades in the water, the performance of the disc brake can be restored immediately after one or two times of braking, but the performance of the friction plate can be restored only after more than ten times of continuous braking. From this point of view, the disc axle is also better than the drum axle in terms of water attenuation performance.

It can be seen that as long as the disc axle is used properly, its safety and reliability can be guaranteed, but remember that for the owners of heavy vehicles or poor driving conditions, for driving safety, if the disc axle is used, it should be used with hydraulic retarder, ABS, EBS, etc.

In addition, when choosing the disc axle, car owners should not blindly believe the words in the advertisement, but also shop around and make more inspections. Only products that can stand the test of the market and users can ensure travel safety. For example, for Darong disc axle, 20Mn2 high-strength alloy seamless steel pipe is selected to ensure the strength, toughness and lightweight of raw materials. At the same time, it is matched with more than a dozen processes such as one-piece heat treatment molding technology, three hole boring finishing and medium frequency induction treatment. The finished products are tested for performance before leaving the factory to ensure that the quality meets the standard, stable and reliable.

ONLINE MESSAGE

24-hour consultation telephone

24-hour consultation telephone

400-6363-989

If you have any needs, you can contact us

CONTACT US

Customer Service Hotline:400-6363-989 Company Address:No. 2, Guoyuan Road, Industrial Park, Quanpu Town, Liangshan County, Jining Cityall rights reserved Darong traffic machinery Co., LTD Lu ICP No. 20025388-2