With the continuous growth of trailer ownership in China, the concept of lightweight has been mentioned more and more. Especially at present, various industries are seriously affected by the epidemic, the economic situation is depressed, but the fuel price continues to rise, which also makes many car owners pay more attention to the fuel economy of vehicles. How to reasonably earn more income within the standard load has become a more concerned issue. Lightweight trailer can meet this demand.

As the name suggests, lightweight Trailer refers to a trailer that is much lighter than ordinary trailer, but has almost no difference in carrying capacity. In general, the lightweight trailer has the same size as the ordinary trailer, but its weight can be more than 15% lighter than the ordinary Trailer.

Because of the current limit of weight charging, the dead weight of the trailer is reduced by one ton, and the owner can pull an extra ton of goods within the standard load range and earn an extra ton of freight.

In addition, in terms of transportation efficiency, lightweight trailers can increase by 30-50%, reduce transportation costs by 30-40%, and reduce fuel consumption by 20-30%. There are many advantages in terms of energy conservation and emission reduction, vehicle cost saving, or improving operation efficiency.

As for the price of light-weight trailer, the price of tractor on the market is generally between 250000 and 320000, and the price of semi-trailer is generally between 60000 and 100000. Of course, the price depends on the brand, performance and model selected by the car owner.

Generally, the trailer is composed of frame, body, traction device, steering device, suspension, traveling system, braking system, signal system, etc. it is a technical test to reduce the weight of the vehicle without affecting the functions of each system.

So, what aspects can lightweight trailers generally achieve "scientific slimming"?

1. High strength steel is selected as the material of girder

As the key bearing component of the trailer, the quality of the girder is directly related to the quality of the trailer to a certain extent. The selection of good materials can reduce the weight of the trailer on the premise of ensuring the bearing capacity of the girder. It is understood that using high-strength steel as girder of warehouse grid semi-trailer can reduce the weight by about one ton compared with ordinary steel. However, the welding process requirements of high-strength steel are relatively strict and more difficult, and the requirements for relevant technology and experience are higher.

In addition, some manufacturers will also choose to use the bending beam, which can also reduce the weight a lot compared with the ordinary T-shaped girder. However, there is a certain gap between the bending beam and the ordinary vehicle beam in terms of strength, so we need to be careful in the selection.

2. Suspension options: air suspension or lightweight leaf spring

The vehicle suspension can choose the lightweight leaf spring. For example, the four piece lightweight leaf spring for the warehouse grid semi-trailer can reduce the weight by about 100kg compared with the ordinary leaf spring. If the air suspension is used, the weight reduction effect is more obvious. Generally, it can reduce the weight by about 500kg and save the weight of the bridge accessories.

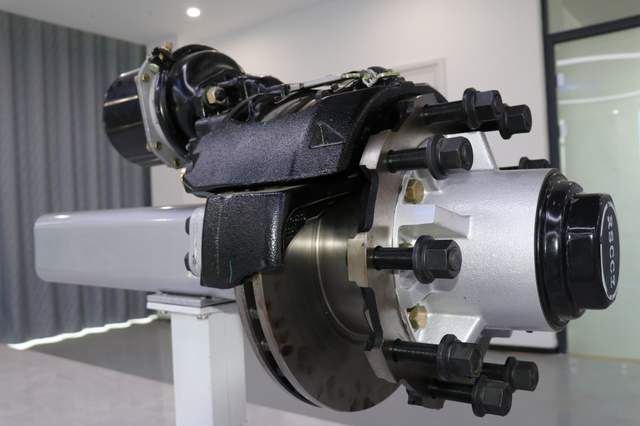

3. Choose high-quality lightweight products for axle

The axle is the key component of the trailer, which is related to the load-bearing, driving and braking functions of the vehicle. In order to realize the lightweight of the body, the axle is also one of the essential ways.

According to the calculation data of Darong axle, the weight of each new disc brake lightweight axle can be reduced by about 15% compared with the ordinary axle. Choosing a lightweight axle can not only reduce the body weight, but also help to save fuel, reduce tire damage and reduce the cost of comprehensive vehicles.

4. Select vacuum tire or ultra wide vacuum tire

According to relevant personnel, vacuum tires are superior to ordinary steel wire tires in weight reduction and heat dissipation. Taking a three axle semi-trailer as an example, if all ordinary steel wire tires are replaced with vacuum tires, the weight can be reduced by about 240 kg. The ultra wide vacuum tire has more obvious advantages in weight reduction, but the ultra wide vacuum tire needs to be made with an extended shaft, which will also increase some weight to a certain extent.

5. Aluminum alloy wheel hub is selected

Generally speaking, the average weight of aluminum alloy wheel hub is about 25-28 kg, and the weight of vacuum steel ring is generally 46 kg. In contrast, it can reduce the weight by nearly half. If aluminum alloy wheels are used with lightweight axles, the body weight can be reduced by about 800-1000 kg, which is about one ton more standard load space.

6. Select new materials for the body and optimize the structure at the same time

Choose better materials, such as high-strength steel, or optimize the trailer structure, such as increasing the spacing between the flower bars of the warehouse grid trailer, or use canvas blocks on the sides, no beam is set on the top of the carriage, and fasten the door with a rope tensioner when heavy load.

ONLINE MESSAGE

24-hour consultation telephone

24-hour consultation telephone

400-6363-989

If you have any needs, you can contact us

CONTACT US

Customer Service Hotline:400-6363-989 Company Address:No. 2, Guoyuan Road, Industrial Park, Quanpu Town, Liangshan County, Jining Cityall rights reserved Darong traffic machinery Co., LTD Lu ICP No. 20025388-2